- MIXDESIGN

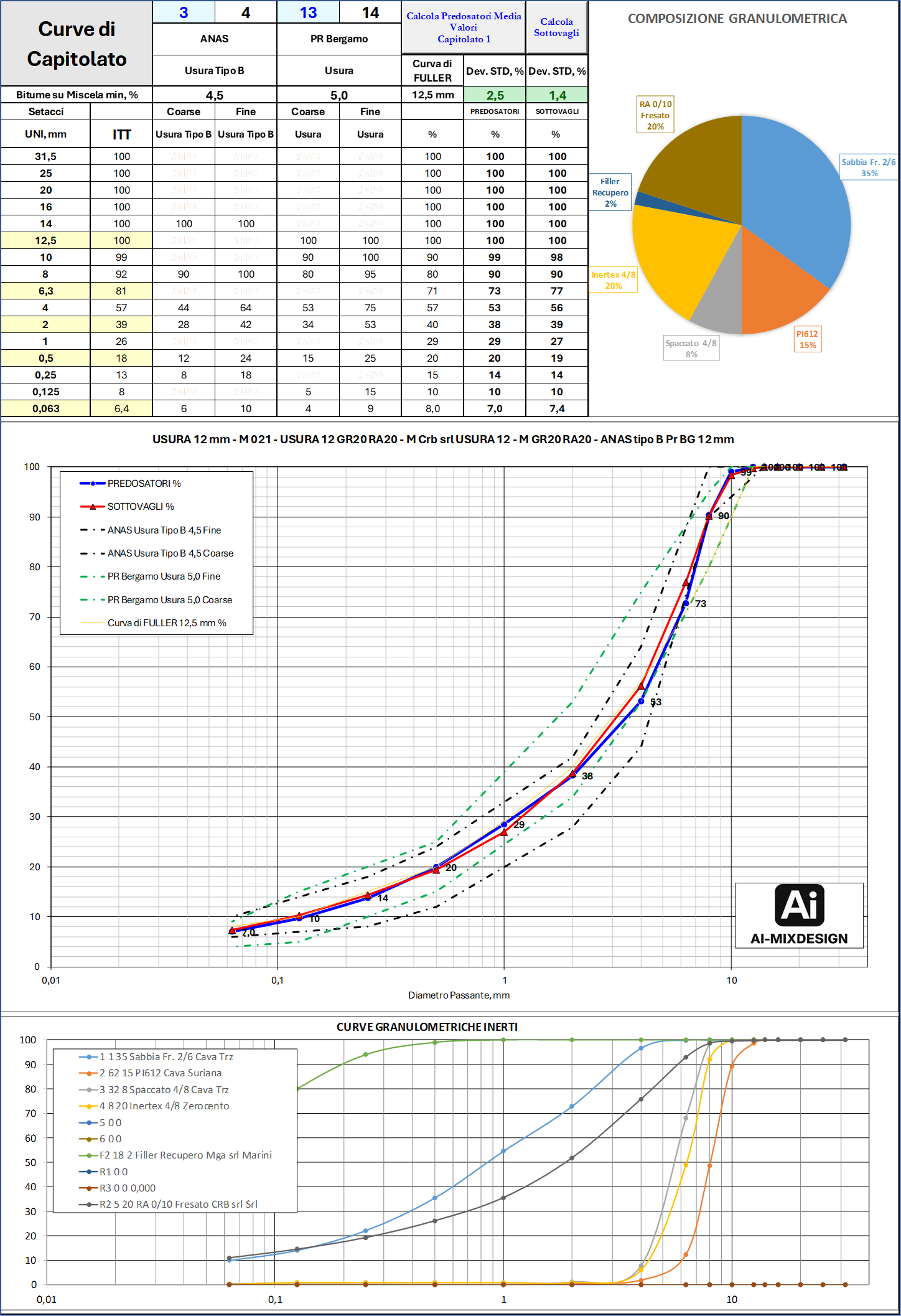

Module dedicated to the creation of optimized asphalt mix recipes. It allows for the processing of recipes compliant with one or more specific specifications, automatically calculates the proportioning of the plant's pre-feeders, and defines the dosage percentages of the aggregates to reproduce the studied gradation curve.

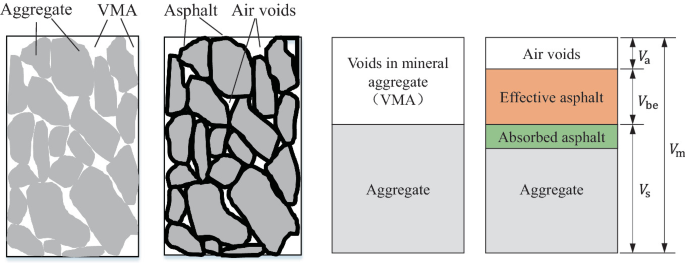

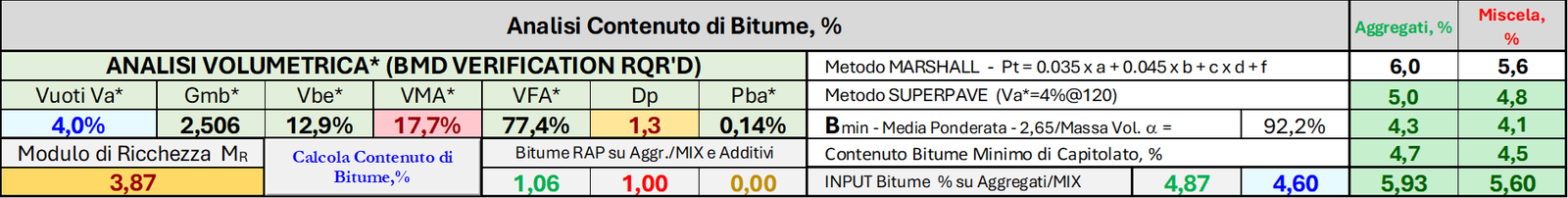

The program determines the optimal quantity of bitumen (OBC) required for compliance with the specifications, based on Marshall or volumetric studies (SUPERPAVE). It also allows for adherence to volumetric limits (VMA, VFA) and analyzes the filler/bitumen ratio based on the chosen void volume (Va).

The final OBC must be verified in the laboratory by meeting the requirements of the performance tests such as Balance Mix Design (Volumetric Mix Design with performance verification).

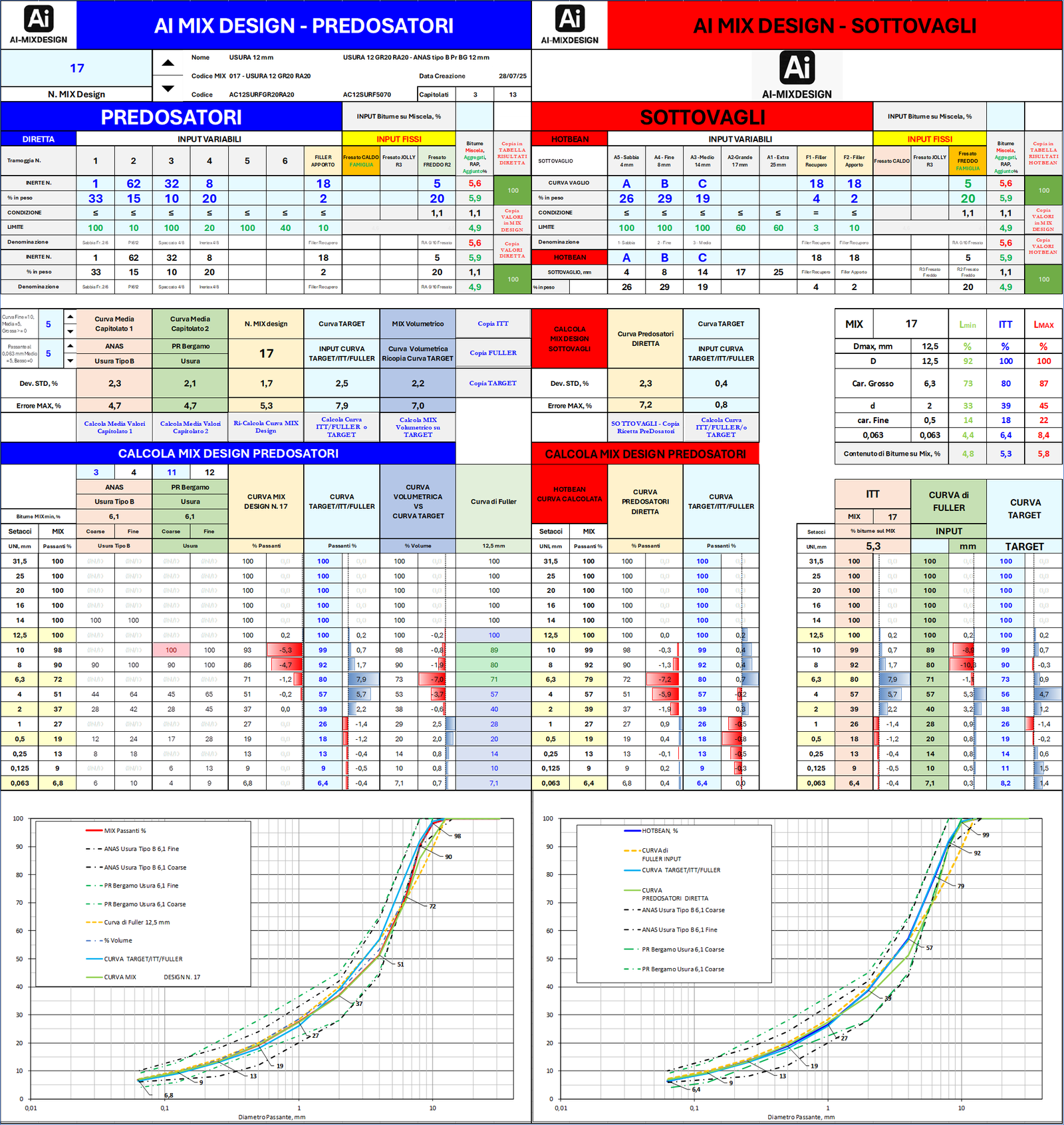

- AI-MIXDESIGN

- Design advanced volumetric curves and allows for compliance with specification curves or replication of specific curves (Fuller, ITT, existing recipes).

- Compare gravimetric and volumetric curves.

- Defines predator and underlay recipes to meet design parameters.

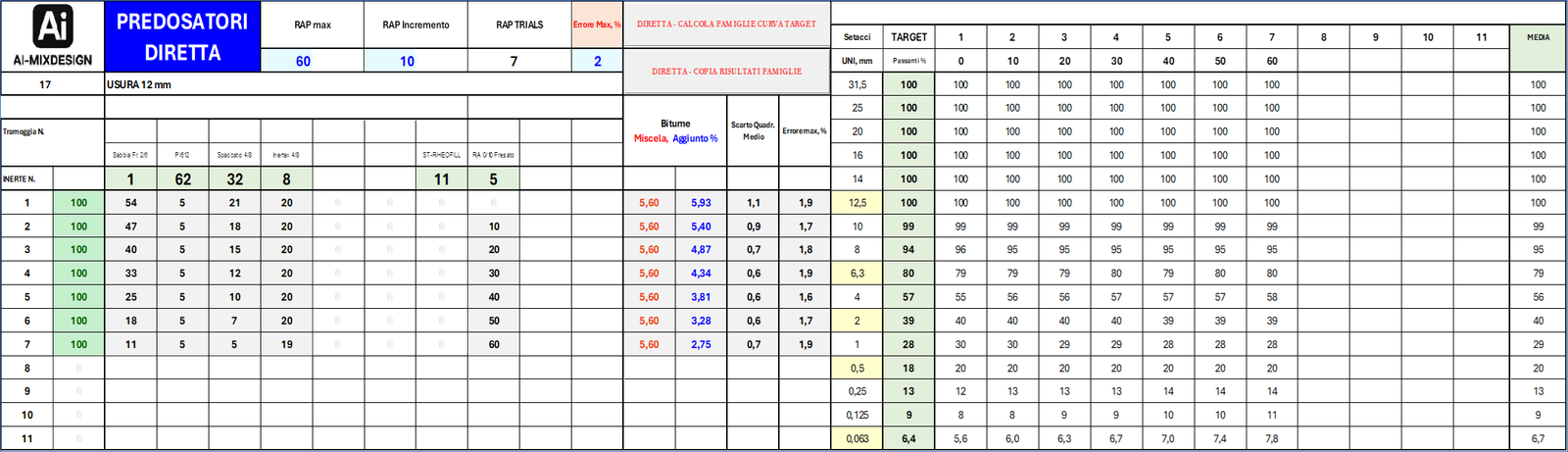

Create product families by varying the content of milled material, keeping the ITT curve and the bitumen content unchanged.

- INERTIA

Manages over 100 types of aggregates, milled materials, and underlay curves. It allows for quick modification of a recipe by changing a parameter and updating all related curves.

- BITUMEN

Manages over 30 types of bitumen with different characteristics and processing/storage temperatures.

- ADDITIVES

It manages over 30 additives with specific dosages (based on total bitumen, mix, milled material, or oxidized bitumen), such as oxides, fibers, polymers, rejuvenators, activators, and bituminous membranes with specific bitumen content.

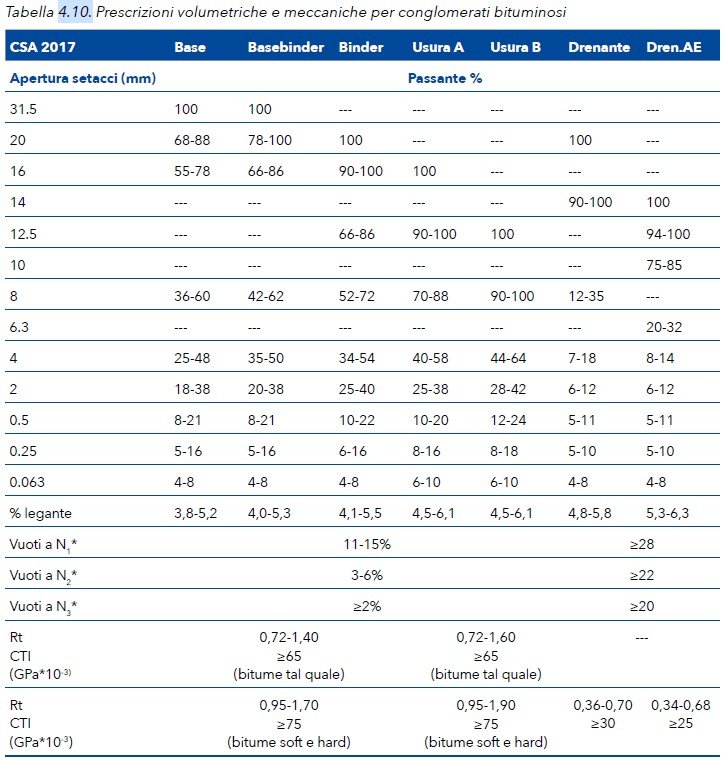

- SPECIFICATIONS CURVES

Manages over 100 prescriptions (ANAS, Highways for Italy, provinces, etc.). Facilitates compliance with specifications during the design and production phases.

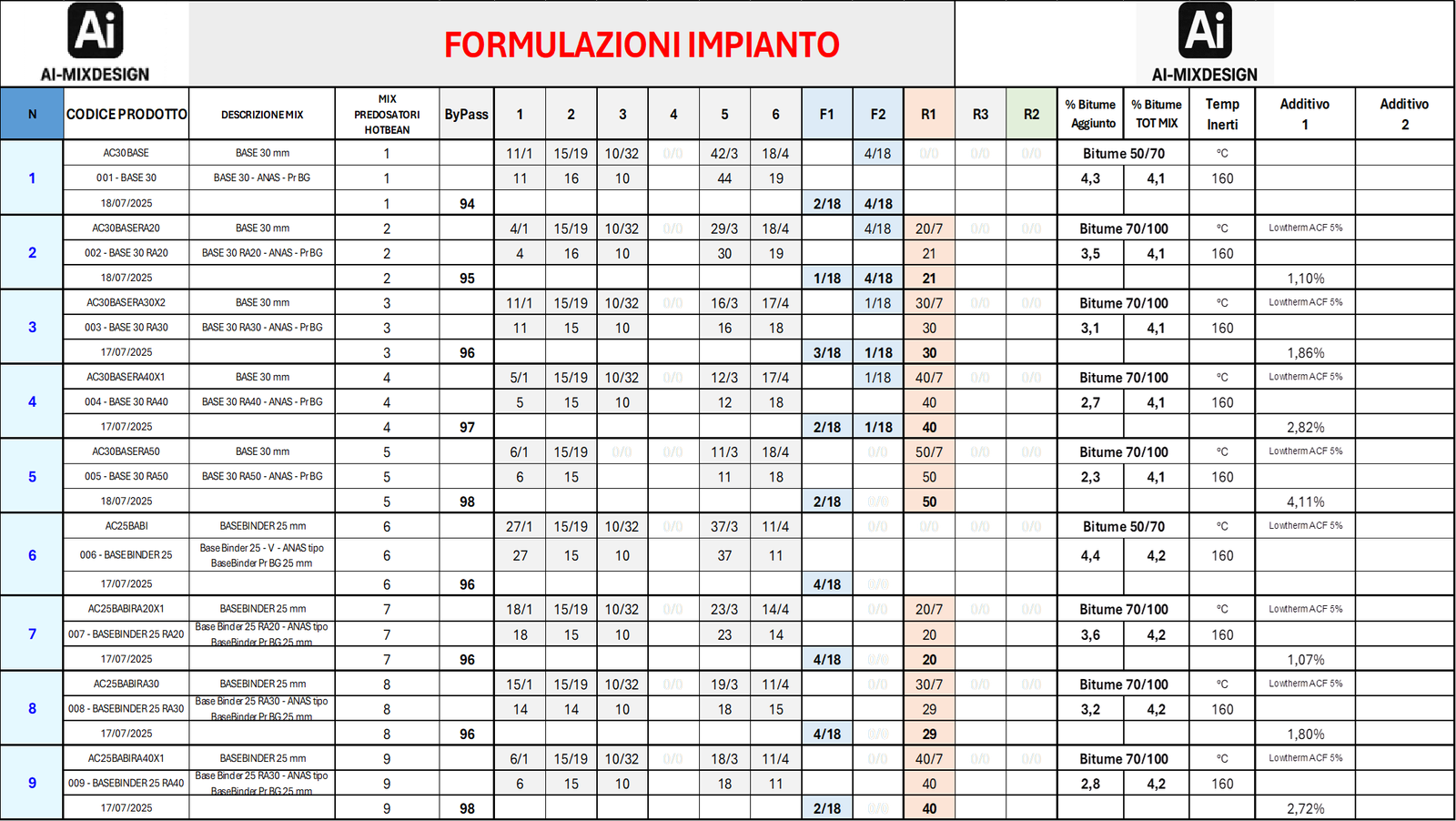

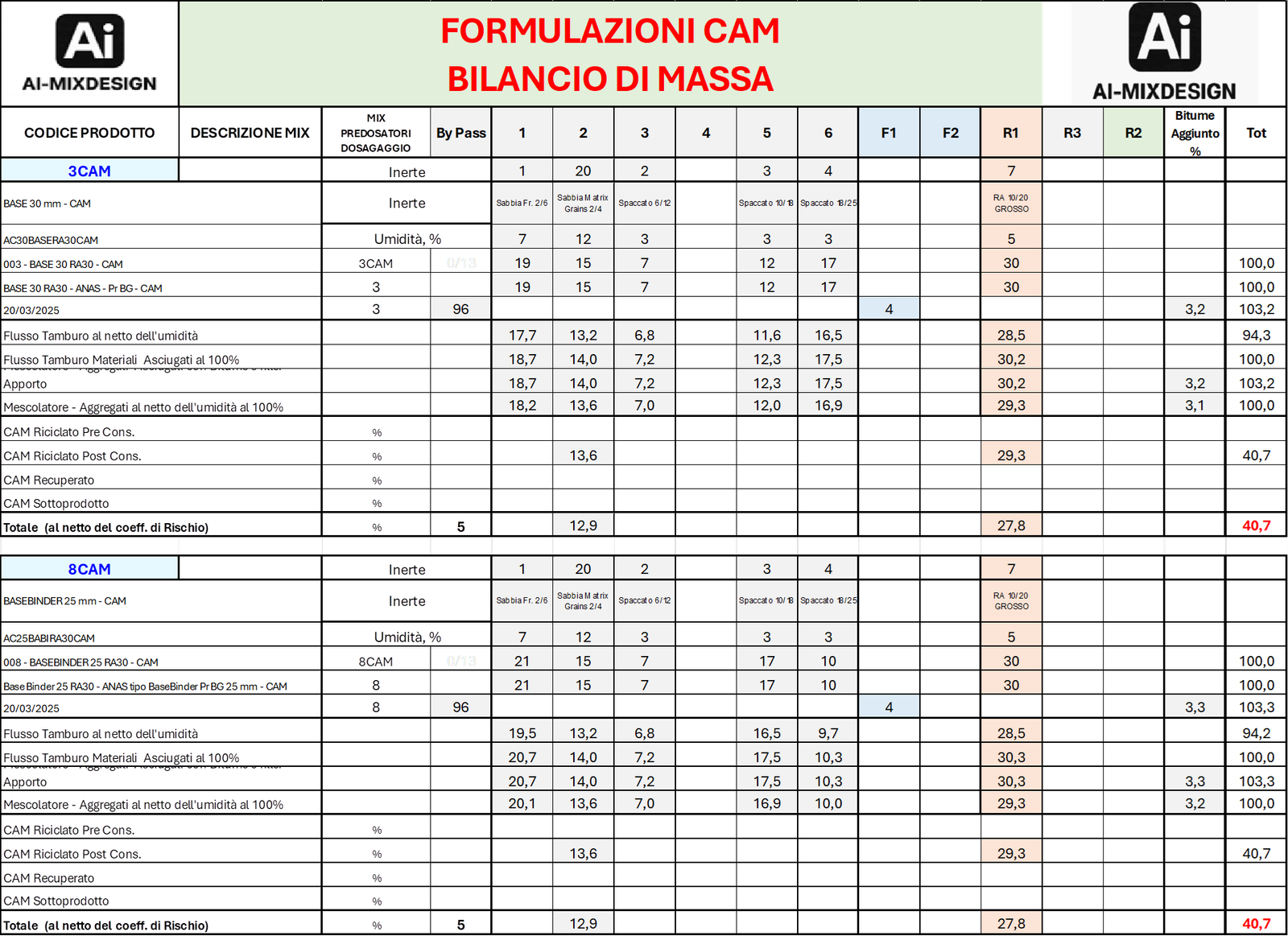

- FORMULATION

Manages production recipes to directly set the asphalt plant. Compatible with Marini and Bernardi plants.

- CAM – Minimum Environmental Criteria

Define the mass balance (PdR88:20) with the percentage quantities of recycled materials, by-products, or recovered materials, as required by the regulations.

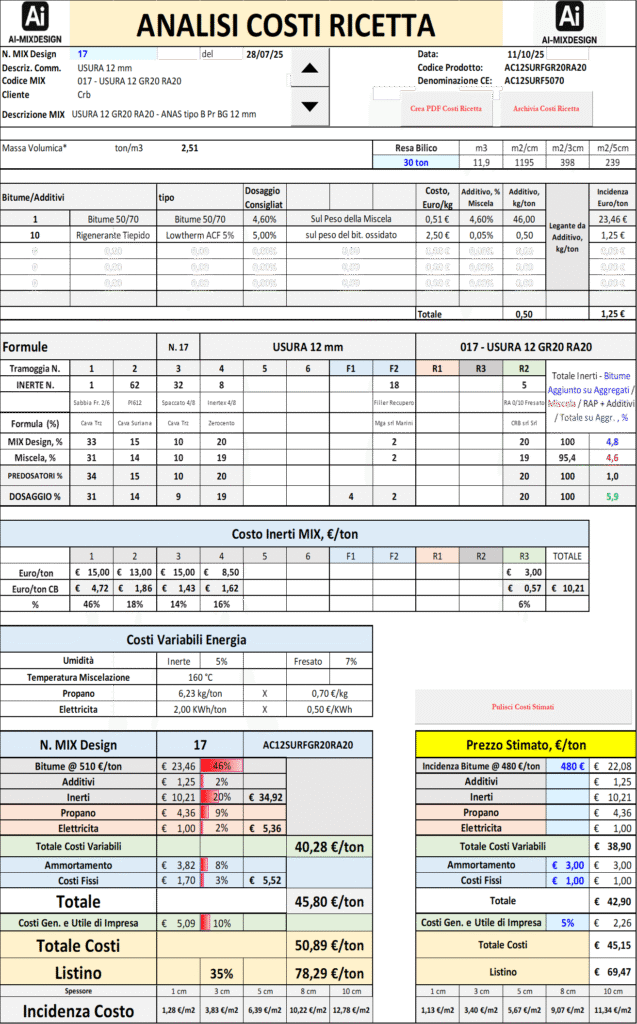

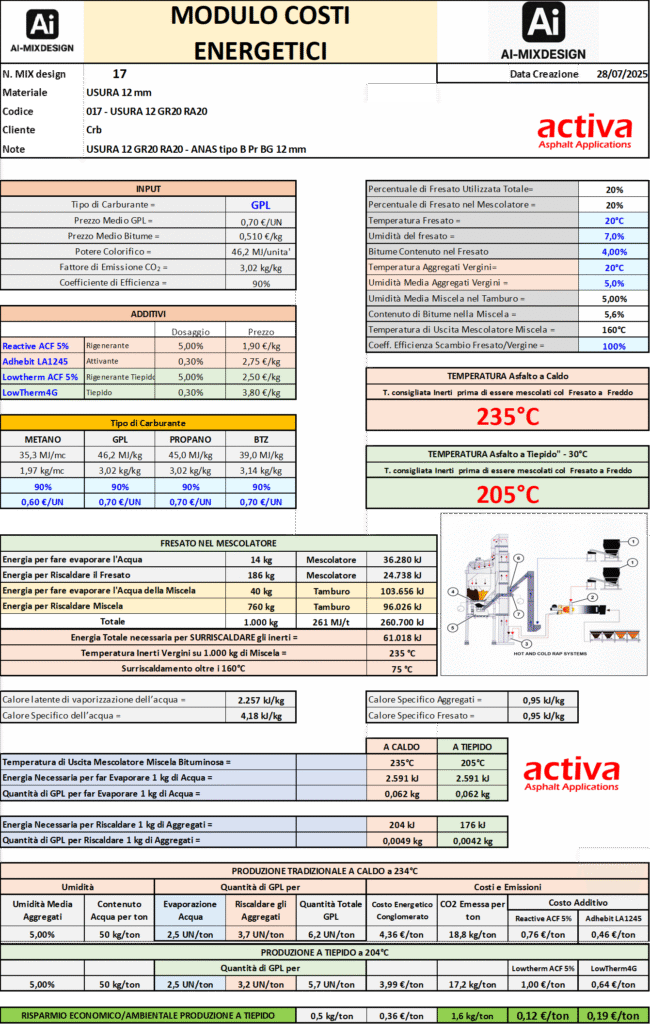

- COST ANALYSIS RECIPE, ENERGY MODULE AND PRICE LIST

- Calculation of industrial costs (components, variable, fixed, profits).

- Analysis of energy consumption as a function of process, temperature, and humidity of the aggregates.

- Creation of an updated price list based on the costs of raw materials and recipes.

- CE CERTIFICATION

Manages standard ITT values, production controls, ITT/DOP declarations, and CE labels.

Allows integrated management of the marking of bituminous mixtures.

Summary map of some modules and their functions

| Module | Main functions |

|---|---|

| MIXDESIGN | Creation of bituminous conglomerate recipes; proportioning of pre-feeders; dosages of hoppers, sub-gravel, filler, milled material, bitumen, and additives; compliance with specifications through Marshall or SUPERPAVE studies. |

| AI-MIXDESIGN | Advanced volumetric curve design; curve replication (Fuller, ITT, recipes); comparison of gravimetric/volumetric curves; creation of families of products by varying the milled material. |

| INERTIA | Management of over 100 aggregates and curves; automatic updating of recipes when a parameter changes. |

| BITUMEN | Management of over 30 types of bitumen with different characteristics and processing/storage temperatures. |

| ADDITIVES | Management of over 30 additives (oxides, fibers, polymers, regenerators, activators, bituminous membranes); specific dosages based on the mixture, milled material, or oxidized bitumen. |

| SPECIFICATIONS CURVES | Management of over 100 prescriptions (ANAS, highways, provinces); compliance with specifications in design and production. |

| FORMULATION | Management of over 100 recipes; direct setting of the asphalt plant; compatible with Marini and Bernardi plants. |

| CAM | Definition of the quantity of recycled materials, by-products, or recovered materials according to current regulations. |

| COST & ENERGY ANALYSIS | Calculation of industrial costs (components, variable, fixed, profits); analysis of energy consumption; creation of updated price list. |

| CE CERTIFICATION | Management of standard ITT values; production controls; ITT/DOP declarations; CE labels; integrated marking of aggregates. |

| Estimation of Quantities and Costs | It allows for the calculation of the quantities of raw materials and their related costs for specific orders or tenders. |

| Penetration Check | Allows you to calculate the residual penetration in recipes with milled material. |